RIVETECH

COATINGS FOR CUSTOM-DESIGNED COMPONENTS

Description

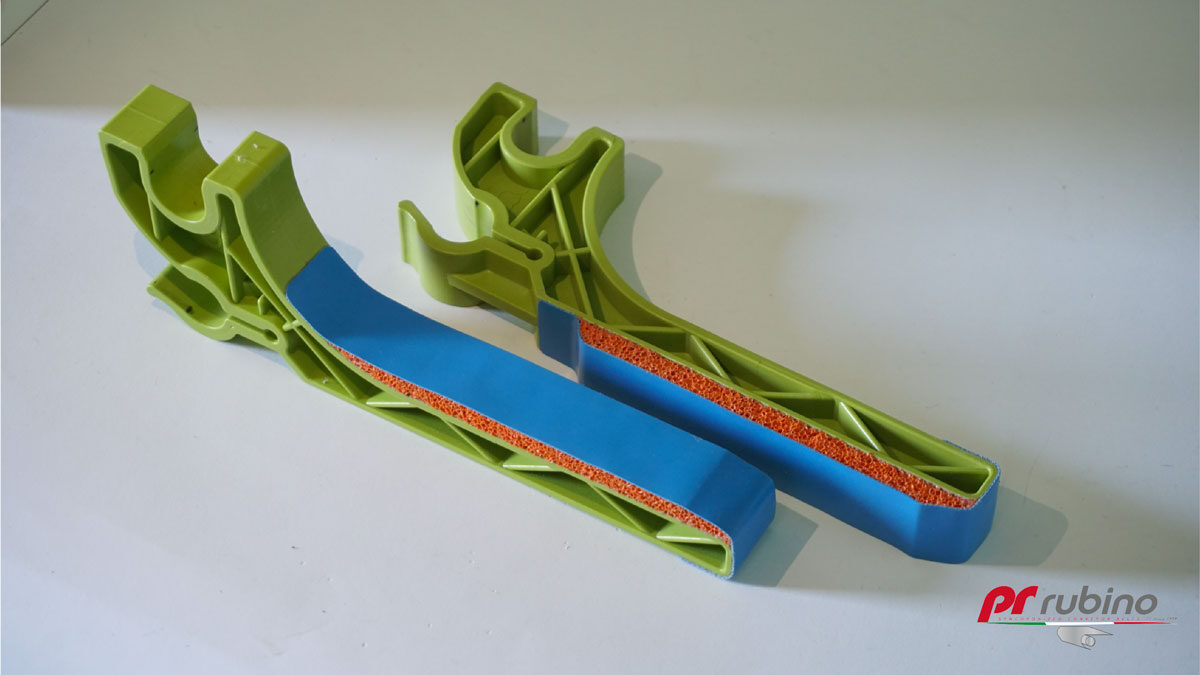

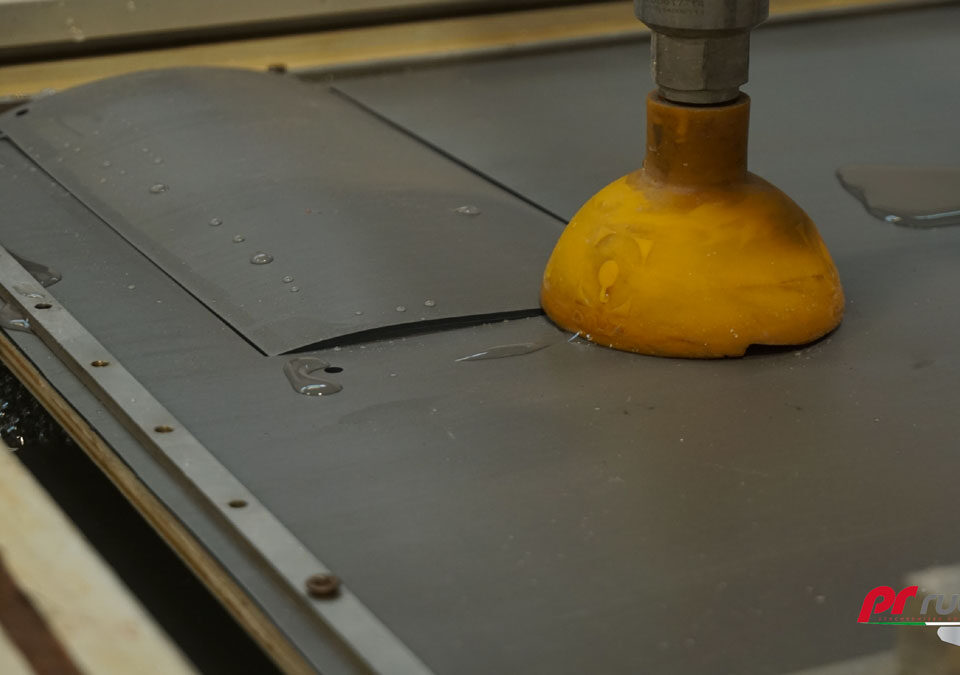

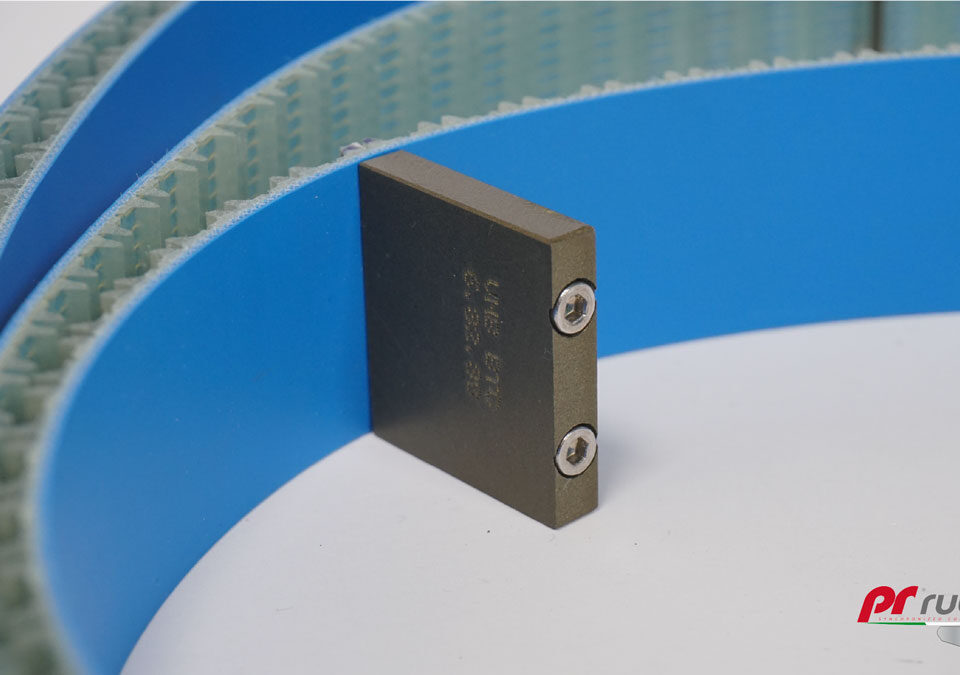

Rivetech is a method of coating metal or plastic components to drawing. This technique is the result of more than 65 years of experience in alchemy and vulcanization. Vulcanization of any type of coating on both rigid and flexible support is possible. The most common coatings applied to custom made components are pvc, polyurethane, expanded rubbers, compact rubbers, and silicone. Thanks to our experience over the years, we can perform double coatings by combining compact and expanded materials. In this way, the expanded material will allow the conveyed product to be compensated while the compact material will serve to protect the expanded one making it last over time.

Advantages

- High degree of customization

- High degree of resistance

- Compensation of conveyed product