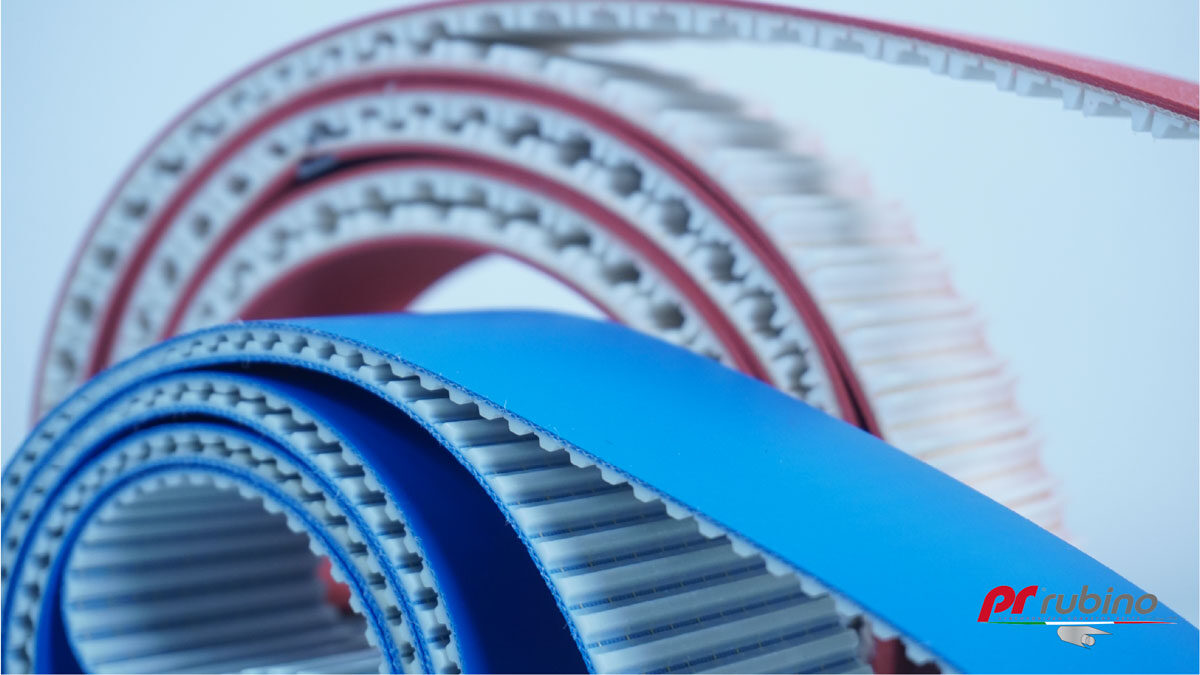

We design, manufacture and customize synchronous conveyor belts. Synchronized conveyor belts represent innovative conveyor and process belts that through special toothing give birth to our range of synchronous belts. This new generation of products allows the synchronization of conveyor belts in different processes, both in the food sector through the Dolphine Bluefood line and in the non-food sector through the Dolphine Multipurpose line. These same toothed and synchronous conveyor belts, through a sector coating, give rise to the Dolphine Sector line.

DOLPHINE

Toothed conveyor and process belts with segmented coating

Description

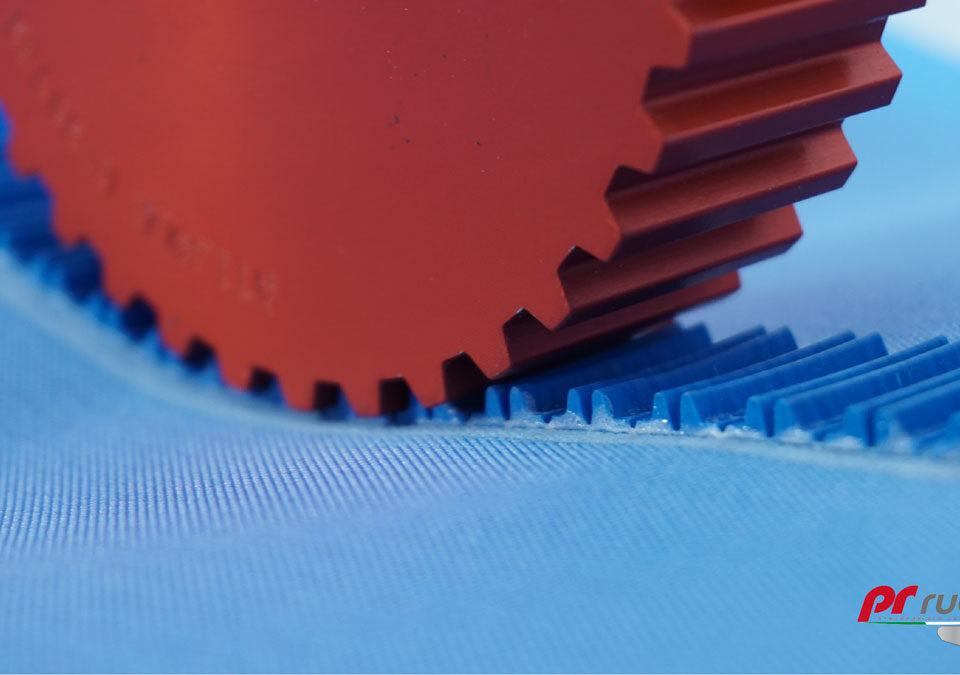

Dolphine toothed conveyor and process belts are next-generation synchronous belts combining the technical features of metric-pitch timing belts with the versatility of conveyor belts. This type of synchronous conveyor belts is produced in both food-grade and non-food-grade versions. The food-grade version is named Bluefood and is designed to ensure safety in direct food contact. The non-food-grade version is called Multipurpose and is made for all other purposes where food certification is not required. Dolphine toothed conveyor belts are created for synchronous product conveying and are used in start & stop, pick and place and bi-directional operations. All conveyor belts can be manufactured in widths ranging from 10 mm to 150 mm with TV10, T10, AT10 and H pitches. For widths greater than 150 mm, the use of conveyor belts with Sharkdrive synchronous toothed guides is recommended.

Advantages

- Produced in a single body by industrial process

- They gear on commercial toothed pulleys

- Can be used with only one toothed pulley, namely the driving pulley

- Can wind up to a 15mm diameter thanks to the TV10 tooth pitch

- Can be equipped and processed like conventional timing belts

GALLERY

VIDEO

SCHEDA TECNICA DOLPHINE BLUEFOOD - NASTRI DI TRASPORTO E DI PROCESSO DENTATI SINCRONIZZATI

SCHEDA TECNICA DOLPHINE MULTIPURPOSE - NASTRI DI TRASPORTO E DI PROCESSO DENTATI SINCRONIZZATI

DOLPHI SECTOR

TOOTHED CONVEYOR AND PROCESS BELTS WITH SEGMENTED COATING

Description

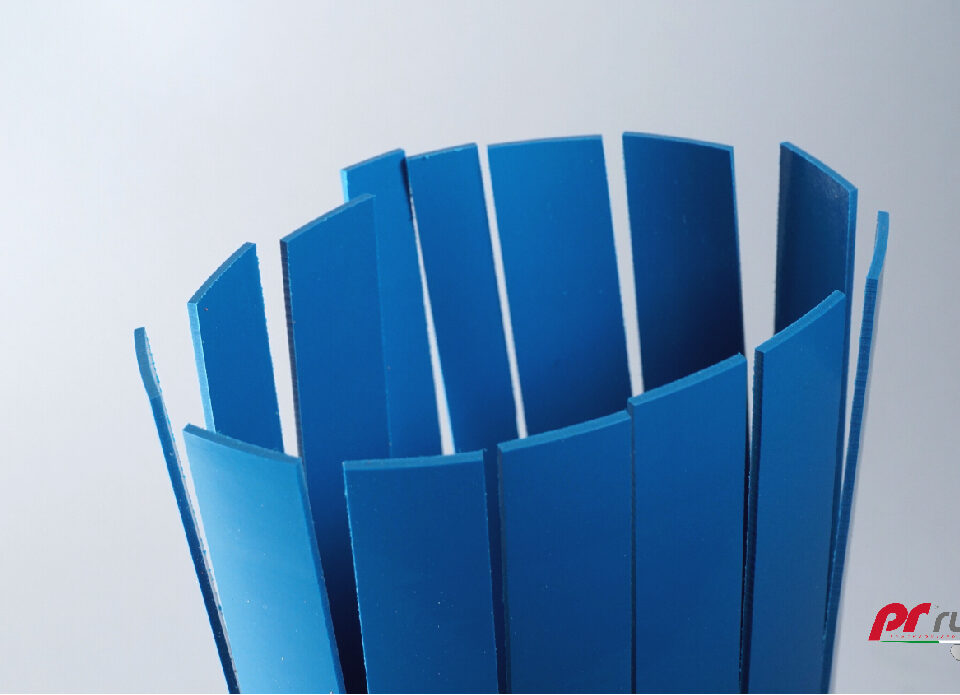

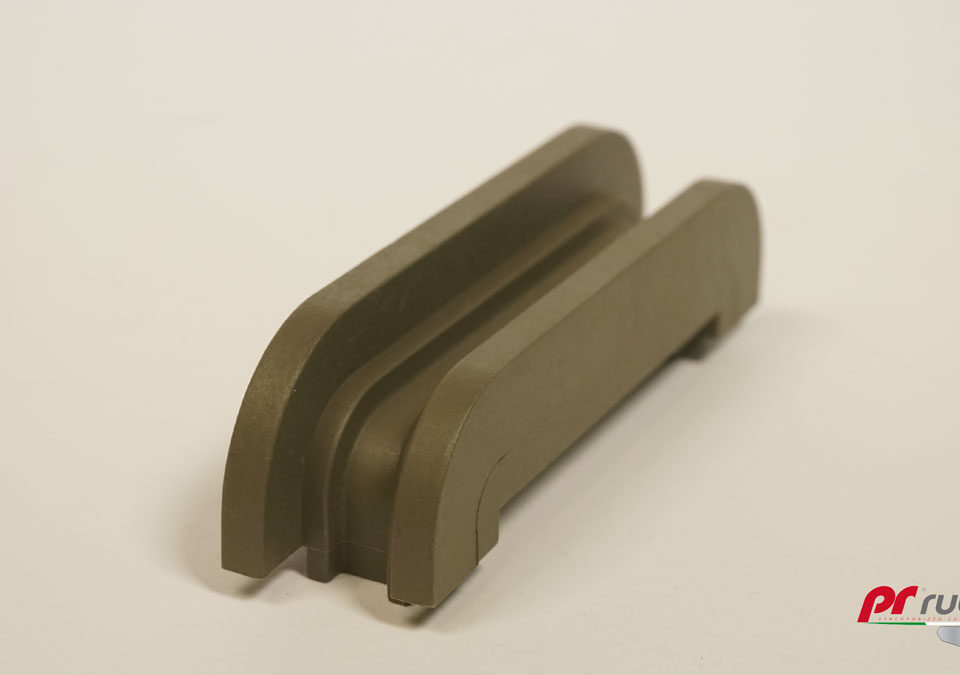

Dolphisector toothed conveyor belts are part of the Dolphine range. Segmented coatings are applied to Dolphisector on the back of the belt. Despite their high thickness, the sectoral structure of the coatings allows wrapping over small diameters. These toothed conveyor belts can be made with foam and compact bi-compound coatings. The compact material that covers the foam ensures greater durability and allows direct food contact thanks to specific certifications of suitability. Dolphisector toothed conveyor belts mesh exclusively on commercial toothed pulleys. These synchronous process belts are used when compensation is needed to avoid deformation or damage to the conveyed product.

Advantages

- Reduced winding diameters due to segmented coating

- Different degrees of elastic memory of the foam material

- They gear on toothed pulleys, preventing slippage

- Can be equipped with openable joints