SHARKDRIVE

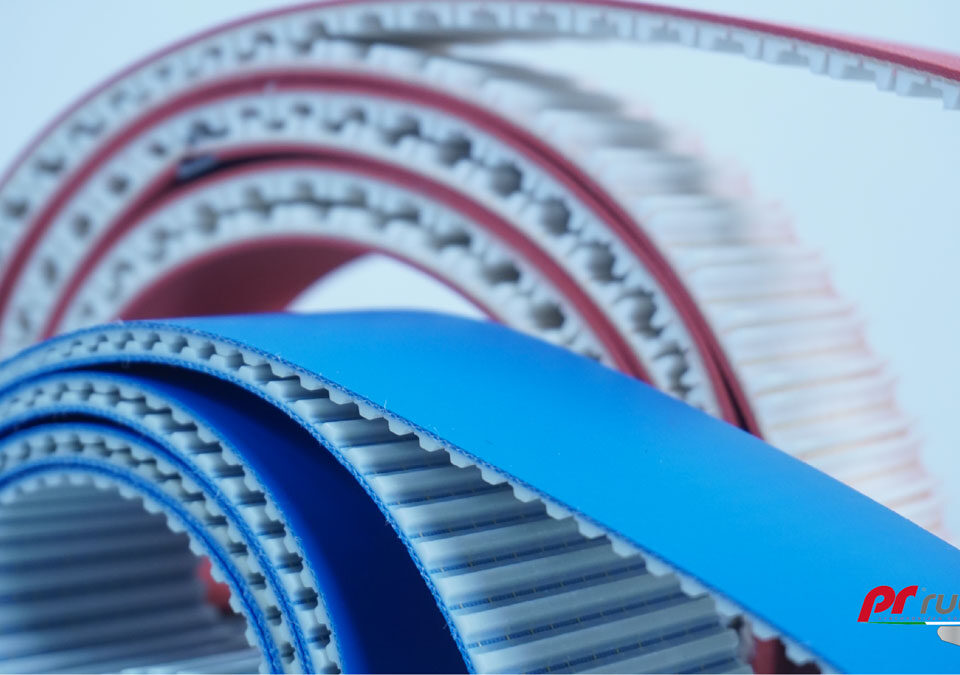

CONVEYOR AND PROCESS BELTS WITH SYNCHRONOUS TOOTHED GUIDES

Description

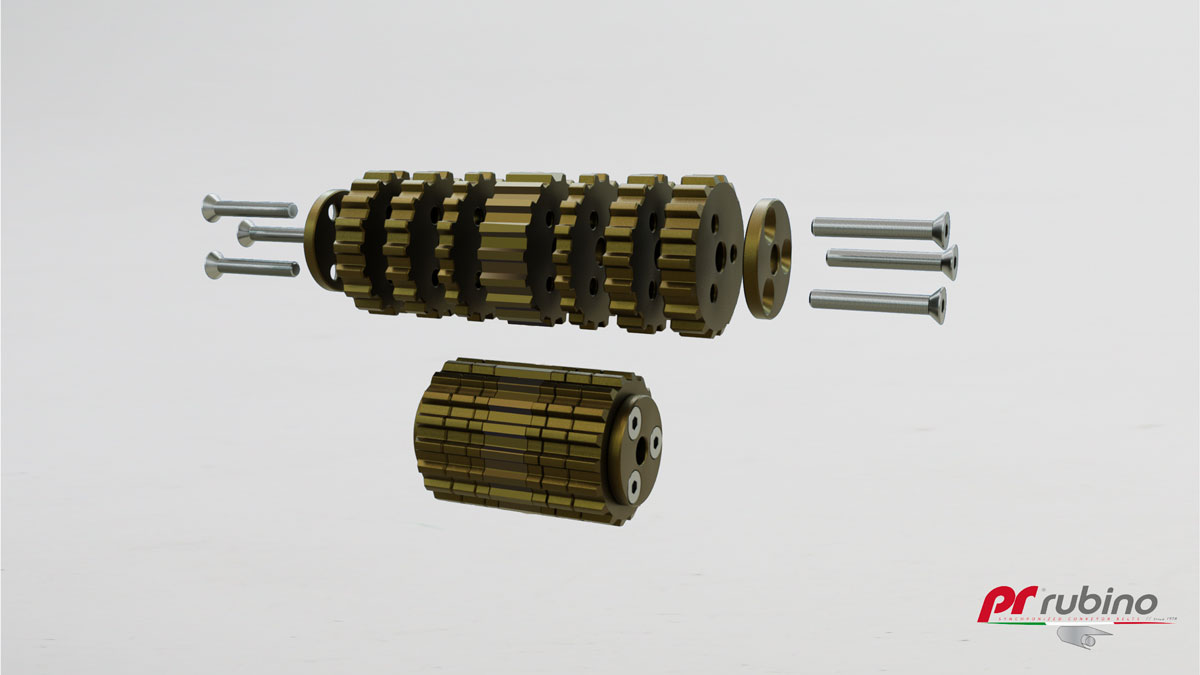

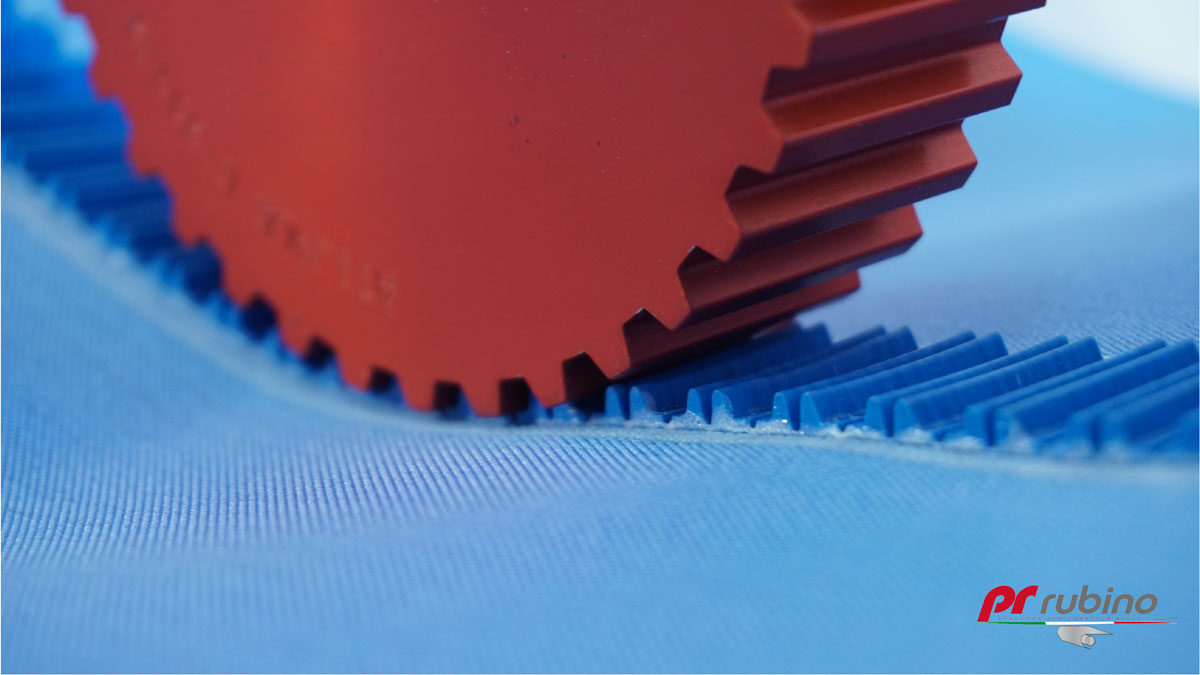

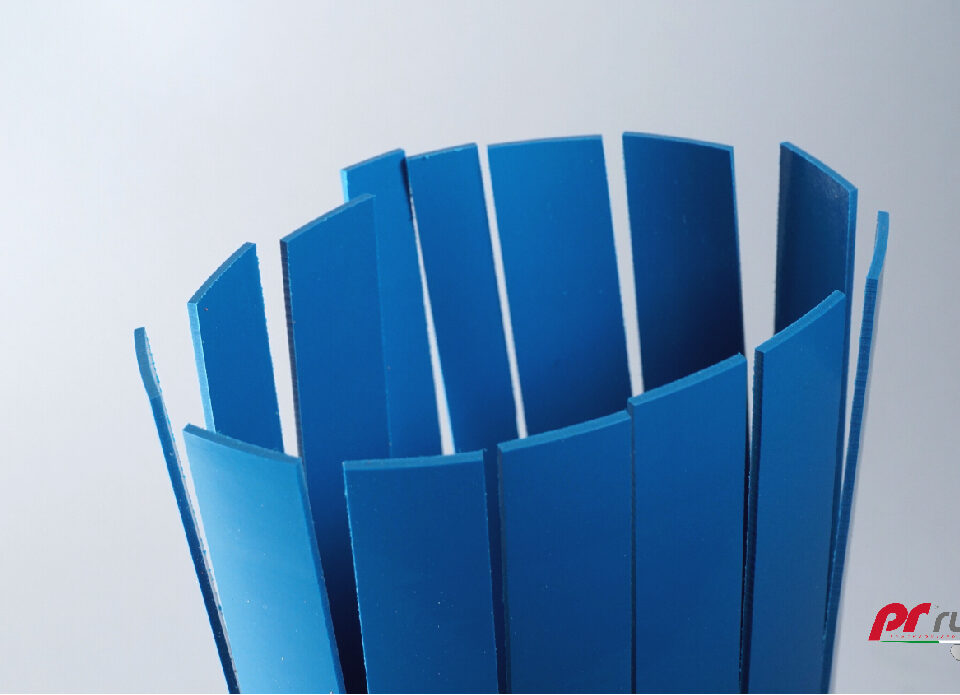

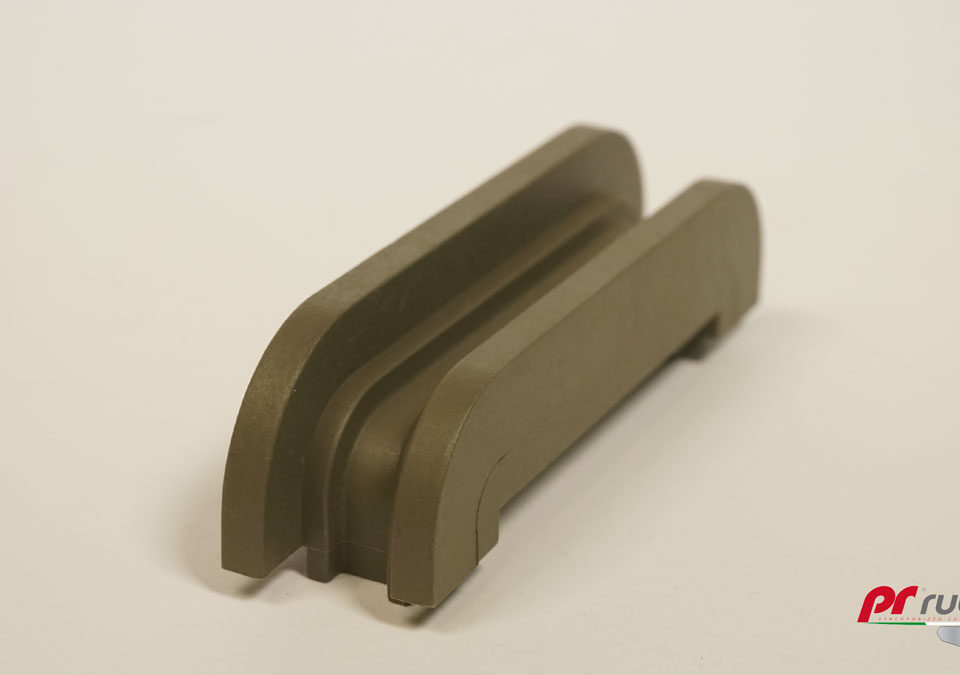

Sharkdrive synchronous conveyor belts are equipped with TV10 and T10 pitch toothed guides applied to the underside of the belt, creating a next-generation hybrid that can synchronize a simple conveyor belt. These process belts are used for synchronous product conveying in pick and place, start & stop operations, bidirectional feeds, and in all general industrial automation. Toothed guides with standard widths of 20, 25, 30, and 40 mm are applied to synchronous conveyor belts between 150 mm and 500 mm wide. For conveyor belts with widths over 500 mm, up to a maximum of 1600 mm, double side guides are applied.

Advantages

- Can only be used with a driving toothed pulley together with smooth ducts

- They gear on toothed pulleys, preventing slippage

- Winding diameter reduced up to 15mm due to TV10 tooth pitch

- Impossibility of guide detachment as all teeth are separated from each other

- Can be equipped with openable joints, outlines and holes