SHARKING

PROCESS BELTS WITH STANDARD SYNCHRONOUS TOOTH GUIDES

Description

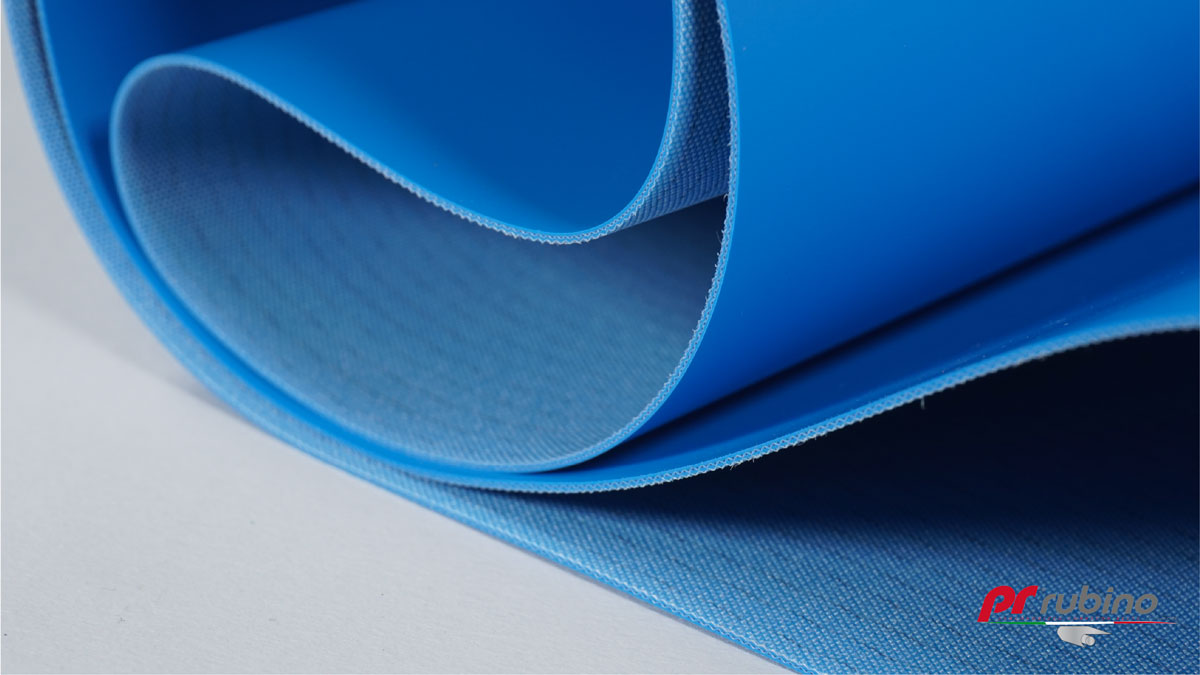

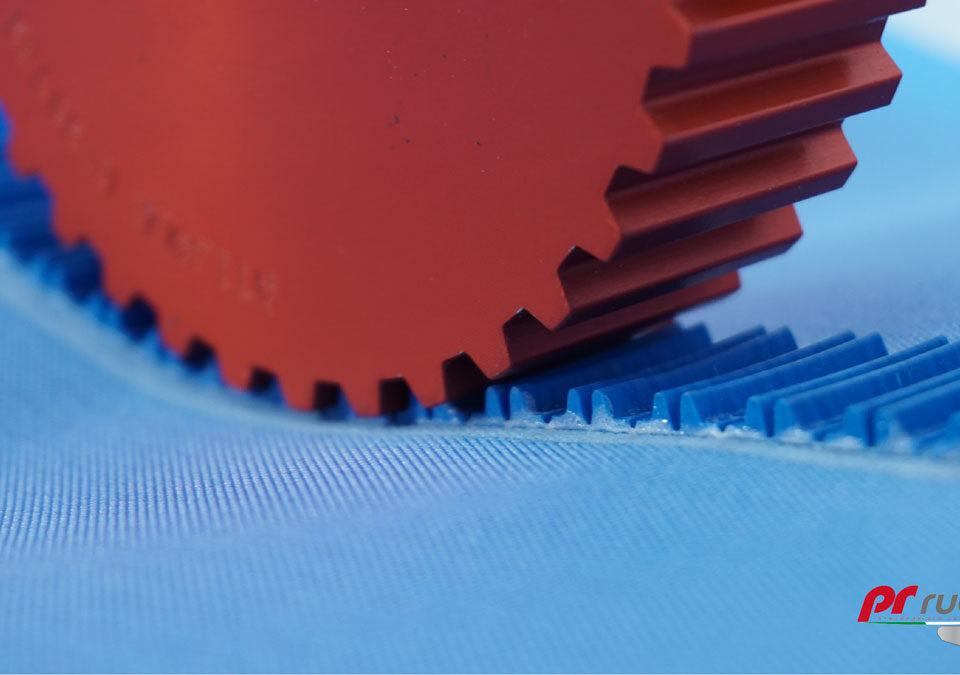

Sharking conveyor belts originate from Sharkdrive synchronous belts of which they share the same technical characteristics and fields of application. The Sharking line was created to industrialize and standardize the tape production process, with the goal of lowering

costs in all applications where there is a planned and continuous demand for the product over time. Sharking toothed guides can be applied to six types of conveyor belts.

Advantages

- Reduced delivery time through coil storage at the warehouse

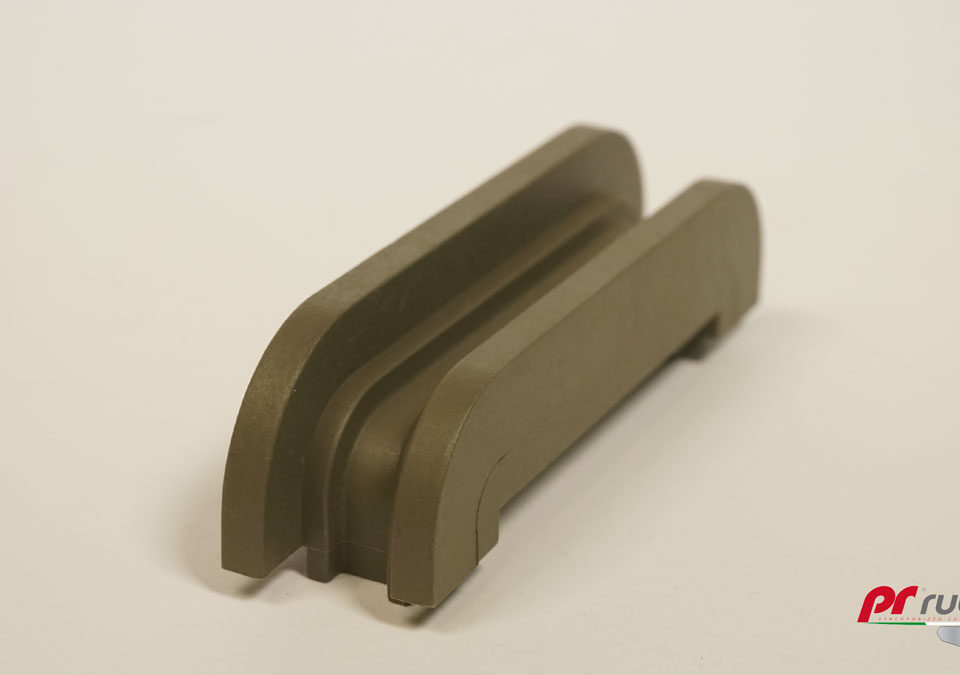

- Can be used only with driving toothed pulley together with smooth ducts

- They gear on toothed pulleys, preventing slippage

- Reduced winding diameter up to 15 mm due to TV10 tooth pitch

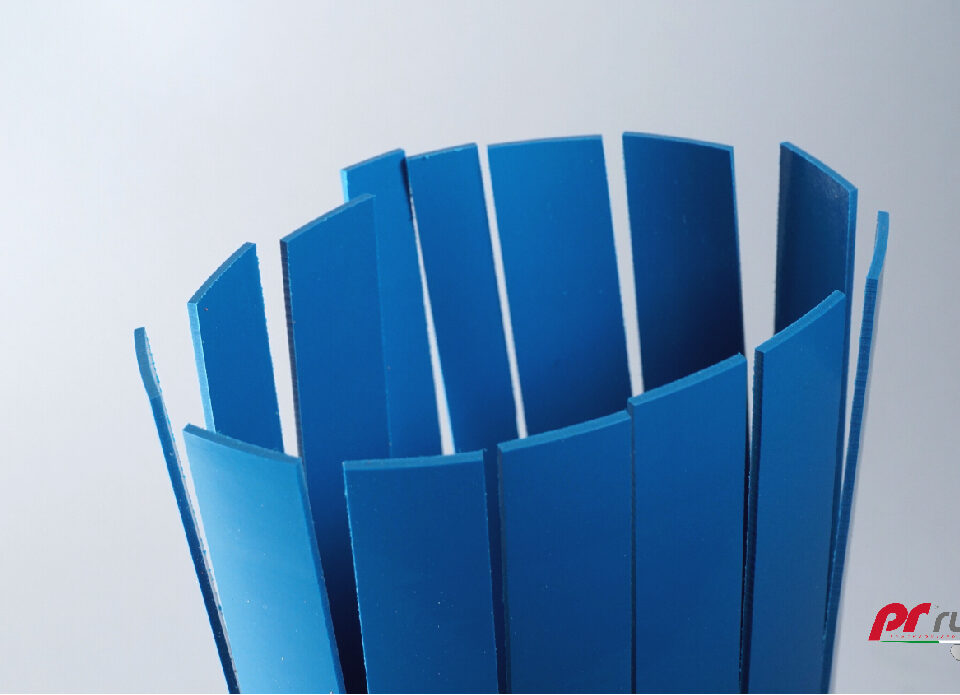

- Impossibility of guide detachment as all teeth are separated from each other

- Can be equipped with openable joints, cleats and holes